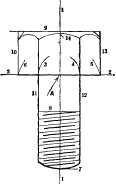

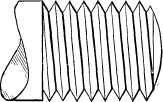

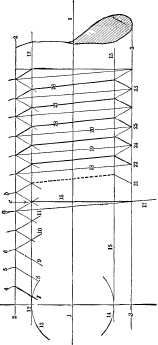

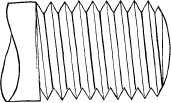

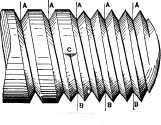

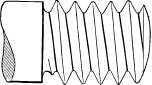

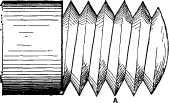

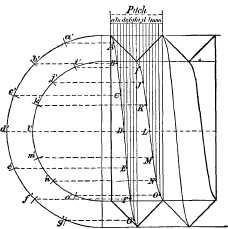

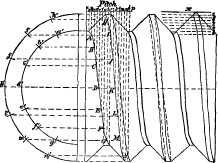

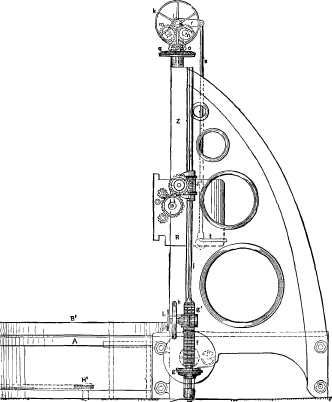

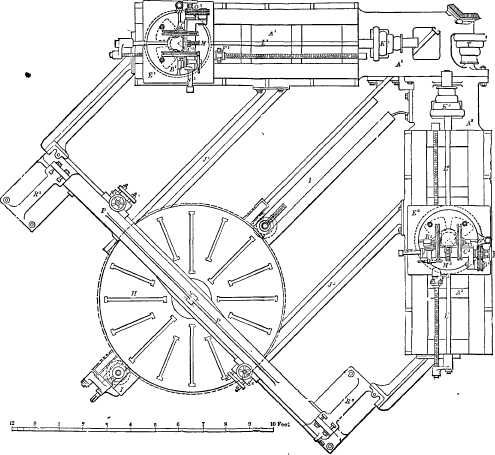

Mechanical Drawing Self-Taught:COMPRISINGINSTRUCTIONS IN THE SELECTION AND PREPARATION OF DRAWING INSTRUMENTS,ELEMENTARY INSTRUCTION IN PRACTICAL MECHANICAL DRAWING;TOGETHER WITHEXAMPLES IN SIMPLE GEOMETRY AND ELEMENTARY MECHANISM, INCLUDING SCREW THREADS, GEAR WHEELS, MECHANICAL MOTIONS, ENGINES AND BOILERS.BY JOSHUA ROSE, M.E.,AUTHOR OF "THE COMPLETE PRACTICAL MACHINIST," "THE PATTERN MAKER'S ASSISTANT," "THE SLIDE VALVE"ILLUSTRATED BY THREE HUNDRED AND THIRTY ENGRAVINGS.PHILADELPHIA:HENRY CAREY BAIRD & CO.,INDUSTRIAL PUBLISHERS, BOOKSELLERS AND IMPORTERS,810 WALNUT STREET.LONDON:SAMPSON LOW, MARSTON, SEARLE & RIVINGTON,CROWN BUILDINGS, 188 FLEET STREET.1887.Copyright byJoshua Rose.1883.PHILADELPHIA.COLLINS, PRINTER[iii] PREFACE.The object of this book is to enable the beginner to learn to make simple mechanical drawings without the aid of an instructor, and to create an interest in the subject by giving examples such as the machinist meets with in his every-day workshop practice. The plan of representing in many examples the pencil lines, and numbering the order in which they are marked, the author believes to possess great advantages for the learner, since it is the producing of the pencil lines that really proves the study, the inking in being merely a curtailed repetition of the pencilling. Similarly when the drawing of a piece, such, for example, as a fully developed screw thread, is shown fully developed from end to end, even though the pencil lines were all shown, yet the process of construction will be less clear than if the process of development be shown gradually along the drawing. Thus beginning at an end of the example the first pencil lines only may be shown, and as the pencilling progresses to the right-hand, the development may progress so that at the other or left-hand end, the finished inked in and shaded thread may be shown, and between these two ends will be found a part showing each stage of development of the thread, all the lines being numbered in the order in which they were marked. This prevents a confusion of lines, and makes it more easy to follow or to copy the drawing. [iv] It is the numerous inquiries from working machinists for a book of this kind that have led the author to its production, which he hopes and believes will meet the want thus indicated, giving to the learner a sufficiently practical knowledge of mechanical drawing to enable him to proceed further by copying such drawings as he may be able to obtain, or by the aid of some of the more expensive and elaborate books already published on the subject. He believes that in learning mechanical drawing without the aid of an instructor the chief difficulty is overcome when the learner has become sufficiently familiar with the instruments to be enabled to use them without hesitation or difficulty, and it is to attain this end that the chapter on plotting mechanical motions and the succeeding examples have been introduced; these forming studies that are easily followed by the beginner; while sufficiently interesting to afford to the student pleasure as well as profit. New York, February, 1883. [v] CONTENTS.

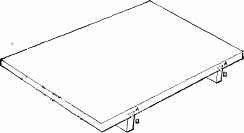

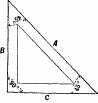

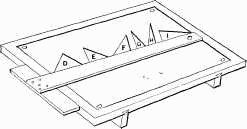

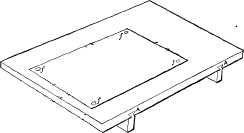

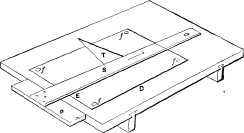

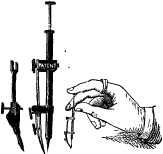

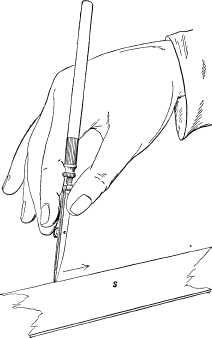

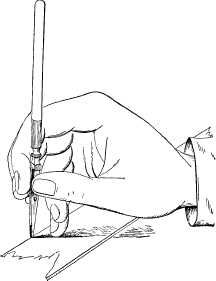

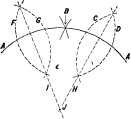

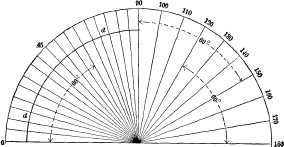

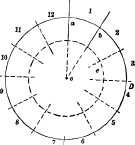

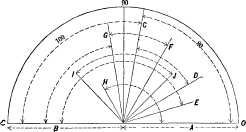

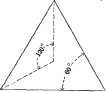

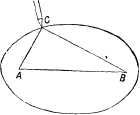

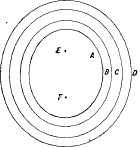

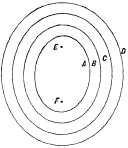

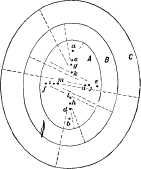

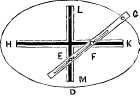

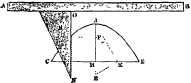

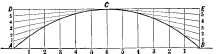

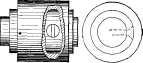

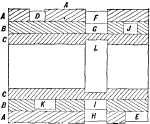

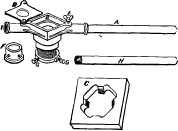

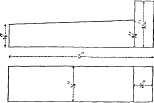

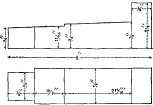

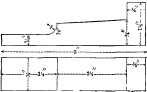

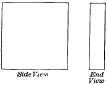

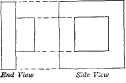

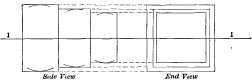

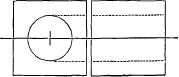

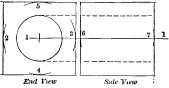

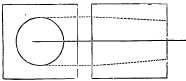

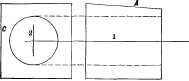

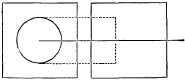

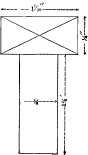

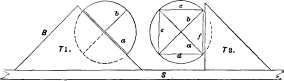

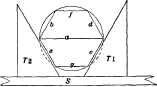

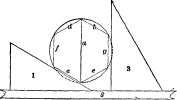

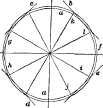

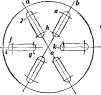

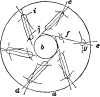

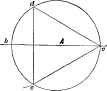

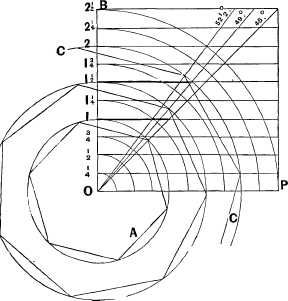

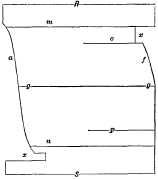

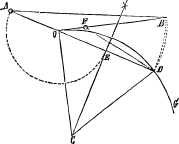

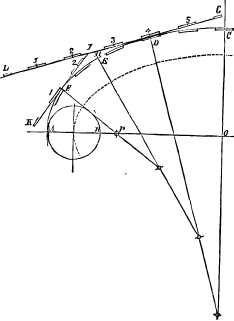

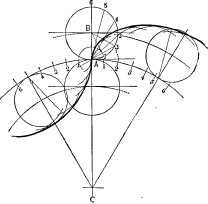

Mechanical DrawingSELF-TAUGHT.CHAPTER I.THE DRAWING BOARD.A Drawing Board should be of soft pine and free from knots, so that it will easily receive the pins or tacks used to fasten down the paper. Its surface should be flat and level, or a little rounding, so that the paper shall lie close to its surface, which is one of the first requisites requisites in making a good drawing. Its edges should be straight and at a right angle one to the other, and the ends of the battens B B in Figure 1[18]should fall a little short of the edge A of the board, so that if the latter shrinks they will not protrude. The size of the board of course depends upon the size of the paper, hence it is best to obtain a board as small as will answer for the size of paper it is intended to use. The student will find it most convenient as well as cheapest to learn on small drawings rather than large ones, since they take less time to make, and cost less for paper; and although they require more skill to make, yet are preferable for the beginner, because he does not require to reach so far over the board, and furthermore, they teach him more quickly and effectively. He who can make a fair drawing having short lines and small curves can make a better one if it has large curves, etc., because it is easier to draw a large than a very small circle or curve. It is unnecessary to enter into a description of the various kinds of drawing boards in use, because if the student purchases one he will be duly informed of the kinds and their special features, while if he intends to make one the sketch in Figure 1 will give him all the information he requires, save that, as before noted, the wood must be soft pine, well seasoned and free from knots, while the battens B should be dovetailed in and the face of the board trued after they are glued and driven in. To true the edges square, it is best to make the two longest edges parallel and straight, and then the ends may be squared from those long edges. THE T SQUARE. Drawing squares or T squares, as they are termed, are made of wood, of hard rubber and of steel. [19] There are several kinds of T squares; in one the blade is solid, as it is shown in Figure 5 on page 20; in another the back of the square is pivoted, so that the blade can be set to draw lines at an angle as well as across the board, which is often very convenient, although this double back prevents the triangles, when used in some positions, from coming close enough to the left hand side of the board. In an improved form of steel square, with pivoted blade, shown in Figure 2, the back is provided with a half circle divided into the degrees of a circle, so that the blade can be set to any required degree of angle at once. THE TRIANGLES. Two triangles are all that are absolutely necessary for a beginner. The first is that shown in Figure 3, [20] which is called a triangle of 45 degrees, because its edge A is at that angle to edges B and C. That in Figure 4 is called a triangle of 60 degrees, its edge A being at 60 degrees to B, and at 30 degrees to C. The edges P and C are at a right angle or an angle of 90 degrees in both figures; hence they are in this respect alike. By means of these triangles alone, a great many straight line drawings may be made with ease without the use of a drawing square; but it is better for the beginner to use the square at first. The manner of using these triangles with the square is shown in Figure 5, in which the triangle, Figure 3, is shown in three positions marked D E F, and that shown in Figure 4 is shown in three positions, marked respectively G H and I. It is obvious, however, that by turning I over, end for end, another position is attained. The usefulness in these particular triangles is because in the various positions shown they are capable of use for drawing a very large proportion of the lines that occur in mechanical drawing. The principal requirement in their use is to hold them firmly to the square-blade [21] without moving it, and without permitting them to move upon it. The learner will find that this is best attained by so regulating the height of the square-blade that the line to be drawn does not come down too near the bottom of the triangle or edge of the square-blade, nor too high on the triangle; that is to say, too near its uppermost point. It is the left-hand edge of the triangle that is used, whenever it can be done, to produce the required line. CURVES. To draw curves that are not formed of arcs or parts of circles, templates called curves are provided, examples of these forms being given in Figure 6. They are made in wood and in hard rubber, the latter being most durable; their uses are so obvious as to require no explanation. It may be remarked, however, that the use of curves gives excellent practice, because they must be adjusted very accurately to produce good results, and the drawing pen must be held in the [22] same vertical plane, or the curve drawn will not be true in its outline. DRAWING INSTRUMENTS. It is not intended or necessary to enter into an elaborate discussion of the various kinds of drawing instruments, since the purchaser can obtain a good set of drawing instruments from a reputable dealer by paying a proportionate price, and must per force learn to use such as his means enable him to purchase. It is recommended that the beginner purchase as good a set of instruments as his means will permit, and that if his means are limited he purchase less than a full set of instruments, having the same of good quality. All the instruments that need be used in the examples of this book are as follows: A small spring bow-pen for circles, a lining pen or pen for straight lines, a small spring bow-pencil for circles, a large bow-pen with a removable leg to replace by a divider leg or a pencil leg, and having an extension piece to increase its capacity. The spring bow-pen should have a stiff spring, and should be opened out to its full capacity to see that the spring acts well when so opened out, keeping the legs stiff when opened for the larger diameters. The purchaser should see that the joint for opening and closing the legs is an easy but not a loose fit on the screw, and that the legs will not move sideways. To test this latter, which is of great importance in the spring bow-pencil as well as in the pen, it is well to close the legs nearly together and taking one leg in [23] one hand and the other leg in the other hand (between the forefinger and thumb), pushing and pulling them sideways, any motion in that direction being sufficient to condemn the instrument. It is safest and best to have the two legs of the bow-pen and pencil made from one piece of metal, and not of two separate pieces screwed together at the top, as the screw will rarely hold them firmly together. The points should be long and fine, and as round as possible. In very small instruments separate points that are fastened with a screw are objectionable, because, in very small circles, they hide the point and make it difficult to apply the instrument to the exact proper point or spot on the drawing. The joints of the large bow or circle-pen should also be somewhat stiff, and quite free from side motion, and the extension piece should be rigidly secured when held by the screw. It is a good plan in purchasing to put in the extension piece, open the joint and the pen to their fullest, and draw a circle, moving the pen in one direction, and then redraw it, moving it in the other direction, and if one line only appears and that not thickened by the second drawing, the pen is a good one. The lead pencil should be of hard lead, and it is recommended that they be of the H, H, H, H, H, H, in the English grades, which corresponds to the V, V, H, of the Dixon grade. The pencil lines should be made as lightly as possible; first, because the presence of the lead on the paper tends to prevent the ink from passing to the paper; and, secondly, because in rubbing out the pencil lines the ink lines are reduced [24] in blackness and the surface of the paper becomes roughened, so that it will soil easier and be harder to clean. In order to produce fine pencil lines without requiring a very frequent sharpening of the pencil it is best to sharpen the pencil as in Figures 7 and 8, so that the edge shall be long in the direction in which it is moved, which is denoted by the arrow in Figure 7. But when very fine work is to be done, as in the case of Patent Office drawings, a long, round point is preferable, because the eye can see plainer just where the pencil will begin to mark and leave off; hence the pencil lines will not be so liable to overrun. In place of the ordinary wood-covered lead pencils there may be obtained at the drawing material stores pencil holders for holding the fine, round sticks of lead, and these are by far the best for a learner. They are easier to sharpen, and will slip in the holder, giving warning when the draftsman is pressing them too hard on the paper, as he is apt to do. The best method of trimming these leads, as also lead pencils after they have been roughly shaped, is with a small fine file, holding the file still and moving the pencil; or a good piece of emery paper or sand paper is good, moving the pencil as before. All lines in pencilling as in inking in should begin at the left hand and be drawn towards the right, or when triangles are used the lines are begun at the bottom [25] and drawn towards the top or away from the operator. The rubber used should not be of a harsh grade, since that will roughen the face of the paper and probably cause the ink to run. The less rubbing out the better the learner will progress, and the more satisfaction he will receive from the results. If it becomes necessary to scratch out it is best done with a penknife well sharpened, and not applied too forcibly to the paper but somewhat lightly, and moved in different and not all in one direction. After the penknife the rubber may sometimes be used to advantage, since it will, if of a smooth grade, leave the paper smoother than the knife. Finally, before inking in, the surface that has been scraped should be condensed again by rubbing some clean, hard substance over it which will prevent the ink from spreading. The end of a paper-cutter or the end of a rounded ivory handled drawing instrument is excellent for this purpose. It is well to use the rubber for general purposes in such a way as to fit it for special purposes; thus, in cleaning the sheet of paper, the rubber may be applied first, as in Figure 9, as at A, and then as at B, and if it be moved sideways at the same time it will wear to the form shown in Figure 10, which will enable it to be applied along a line that may require to be rubbed out without removing other and neighboring [26] lines. If the rubber is in the form of a square stick one end may be bevelled, as in Figure 11, which is an excellent form, or it may be made to have a point, as in Figure 12. The object is in each case to enable the rubber action to be confined to the desired location on the paper, so as to destroy its smooth surface as little as possible. For simple cleaning purposes, or to efface the pencil lines when they are drawn very lightly, squares of sponge-rubber answer admirably, these being furnished by the dealers in drawing materials. A piece of bread will answer a similar purpose, but it is less convenient. For glazed surface paper, as Bristol-board, the smoothest rubber must be used, the grade termed velvet rubber answering well. THE DRAWING PAPER. Whatever kind of drawing paper be used it should be kept dry, or the ink, however good it may be, will be apt to run and make a thick line that will not have the sharp, clean edges necessary to make lines look well. Drawing paper is made in various qualities, kinds, [27] and forms, as follows: The sizes and names of paper made in sheets are: Cap, 13 × 16 inches. the thickness of the sheets increasing with their size. Some sheets of paper are hot pressed, to give a smoother surface, and thus enable cleaner-edged lines to be drawn. For large drawings paper is made in rolls of various widths, but as rolled paper is troublesome to lay flat upon the drawing board, it is recommended to the learner to obtain the sheets, which may be laid sufficiently flat by means of broad headed pins, such as shown in Figure 13, which are called thumb tacks. These are forced through the paper into the board at each corner, as in Figure 14 at f. On account of the large diameter of the stems of these thumb tacks, which unduly pierce and damage the board, and on account also of their heads, by reason of their thickness, coming in the way of the [28] square blade, it will be found preferable to use the smallest sizes of ordinary iron tacks, with flat heads, whose stems are much finer and heads much thinner than thumb tacks. The objection to ordinary tacks is that they are more difficult to remove, but they are, as stated, more desirable for use. If the paper is nearly the full size of the board, it does not much matter as to its precise location on the board, but otherwise it is best to place it as near the left-hand edge of the board as convenient, as is shown in Figure 14.[29] The lower edge, D, Figure 15, of the paper, however, should not be placed too near the edge, A, of the board, because if the end P of the square back comes down below the edge of the board, it is more difficult to keep the square back true against the end of the board. The paper must lie flat upon and close to the surface of the board, and a sufficient number of tacks must be used to effect this purpose. Drawings that are to be intricate, or to contain a great many lines, as a drawing of an engine or of a machine, are best pasted or glued all around the edges of the paper, which should first be dampened; but as the learner will scarcely require to make such drawings until he is somewhat familiar with and well practised in the use of the instruments, this part of the subject need not be treated here. TRACING PAPER. For taking tracings from drawings tracing paper or tracing cloth is used. They require to be stretched tightly and without wrinkles upon the drawing. To effect this object the mucilage should be thick, and the tracing paper should be dampened with a sponge after it is pasted. It must be thoroughly dry before use, or the ink will run. Tracing cloth must be fastened by pins or thumb tacks, and not dampened. The drawing should be made on the polished side of the cloth, and any coloring to be done should be on the other side, and done after the tracing is removed from the drawing. [30] THE INK. India ink should always be used for mechanical drawing: First, because it lies upon and does not sink into the paper, and is, therefore, easily erased; and, secondly, because it does not corrode or injure the drawing instruments. India ink is prepared in two forms—in the stick and in a liquid form. The stick ink is mixed in what are termed saucers, or cabinet saucers, one being placed above the other, so as to exclude the dust from settling in it, and also to prevent the rapid evaporation to which it is subject. The surface of the saucer should be smooth, as any roughness grinds the ink too coarsely, whereas the finer it is ground or mixed the easier it will flow, the less liability to clog the instruments, and the smoother and more flat it will lie upon the paper. In mixing the ink only a small quantity of water should be used, the stick of ink being pressed lightly upon the saucer and moved quickly, the grinding being continued until the ink is mixed quite thickly. This will grind the ink fine as it is mixed, and more water may be added to thin it. It is best, however, to let the ink be somewhat thick for use, and to keep it covered when not in use; and though water may be added if it gets too thick, yet ink that has once dried should not be mixed up again, as it will not work so well after having once dried. Of liquid inks the Higgins ink is by far the best, being quite equal to and much more convenient for use than the best stick ink. [31] The difference between a good and an inferior India ink lies chiefly in the extent to which the lamp-black, which is the coloring matter, forms with the water a chemical solution rather than a mechanical mixture. In inferior ink the lamp-black is more or less held in suspension, and by prolonged exposure to the air will separate, so that on being spread the solid particles will aggregate by themselves and the water by itself. This explains why draughtsmen will, after the ink has been exposed to the air for an hour or two, add a drop of mucilage to it; the mucilage thickening the solution, adding weight to the water, and deferring the separation of the lamp-black. A good India ink is jet black, flows easily, lies close to, does not stand upon or sink into the paper, and has an even lustre, the latter being an indication of fineness. The more perfect the incorporation of the lamp-black with the water the easier the ink will flow, the less liable it is to clog the instruments, the more even and sharp the edges of the lines, and the finer the lines that may be drawn. Usually India ink can only be tested by actual trial; but since it is desirable to test before purchasing it, it may be mentioned that one method is to mix a little on the finger nail, and if it has a "bronzy" gloss it is a good indication. It should also spread out and dry without any tendency to separate. The best method of testing is to mix a very little, and drop a single drop in a tumbler of clear water. The best ink will diffuse itself over the surface, and if the water is disturbed will diffuse itself through the water, leaving it translucent and black, with a slight [32] tinge of bronze color. A coarser ink will act in a similar manner, but make the water somewhat opaque, with a blue-black, or dull, ashy color. A still coarser ink will, when diffused over the surface of the water, show fine specks, like black dust, on the surface. This is readily apparent, showing that the mixture of the ink is not homogeneous. When it is an object to have the lines of a drawing show as black as possible, as for drawings that are to be photo-engraved, the ink should be mixed so thickly as to have a tendency to lift when a body, such as a lead pencil, is lifted out of it. For Patent Office drawings some will mix it so thickly that under the above test it appears a little stringy. The thicker the ink can be used the better, because the tendency of the carbon to separate is less; and it is for this reason that the test mentioned with a tumbler of water is so accurate. When ink is to be used on parchment, or glossy tracing-paper, it will flow perfectly if a few drops of ox-gall be mixed with it; but on soft paper, or on bristol board, this will cause the ink to spread. For purposes of measurement, there are special rules or scales of steel and of paper manufactured. The steel rules are finely and accurately divided, and some are of triangular form, so that when laid upon the paper the lines divided will lie close to the paper, and the light will fall directly on the ruled surface. Triangular rules or scales are therefore much superior to flat ones. The object of having a paper rule or scale is, that the paper will expand and contract under varying degrees of atmospheric moisture, the same as the drawing paper does. [33] Figure 16 represents a triangular scale, having upon it six different divisions of the inch. These are made in different patterns, having either decimal divisions or the vulgar fractions. Being made of steel, and nickel-plated, they are proof against the moisture of the fingers, and are not subject to the variation of the wooden scale. CHAPTER II.THE PREPARATION AND USE OF THE INSTRUMENTS.The points of drawing instruments require to be very accurately prepared and shaped, to enable them to make clean, clear lines. The object is to have the points as sharp as they can be made without cutting the paper, and the curves as even and regular as possible. The lining pen should be formed as in Figure 17, which presents an edge and a front view of the points. The inside faces should be flat across, and slightly curved in their lengths, as shown. If this curve is too great, as shown exaggerated in Figure 18, the body of the ink lies too near the point and is apt to flow too freely, running over the pen-point and making a thick, ragged line. On the other hand, if the inside faces, between which the ink lies, are too parallel and narrow near the points, the ink dries in the pen, and renders a too frequent cleaning necessary. Looking at the face of the pen as at A in Figure 17, its point should have an even curve, as shown, the edge being as sharp as it can be made without cutting the drawing paper. Upon this quality depends the fineness and cleanness of the lines it will make. This thin edge should extend [35] around the curve as far as the dotted line, so that it will be practicable to slant the pen in either of the directions shown in Figure 19; and it is obvious that its thickness must be equal around the arc, so that the same thickness of line will be drawn whether the pen be held vertical or slanted in either direction. The outside faces of the pen should be slightly curved, so that when held vertically, as in Figure 20 (the dotted line representing the centre of the length of the instrument), and against the square blade S, the point will meet the paper a short distance from the lower edge of S as shown. By this means it is not necessary to adjust the square edge exactly coincident with the line, but a little way from it. This is an advantage for two reasons: first, the trouble of setting the square-edge exactly coincident is avoided, and, secondly, the liability of the ink to adhere to the edge of the square-blade and flow on to the paper and make a thick, ragged line, is prevented. The square being set as near to the line as desired, the handle may be held at such an angle that the pen-point will just meet the line when sloped either as in Figure 21 or 22. If, however, the slope be too much in the direction shown in Figure 21, practice is necessary to enable the drawing of straight lines if they be long ones, because any variation in the angle of the [36] instrument to the paper obviously vitiates the straightness of the line. If, on the other hand, the square be too close to the line, and the pen therefore requires to be sloped as in Figure 22, the ink flowing from the pen-point is apt to adhere to the square-edge, and the result will be a ragged, thick line, as shown in Figure 23. Each of the legs should be of equal thickness at the pen-point edge, so that when closed together the point will be in the middle of the edge. The width and curve of each individual point should be quite equal, and the easiest method of attaining this end is as follows: Take a small slip of Arkansas oil-stone, and with the pen-points closed firmly by the screw trim the pen-edges to the required curve as shown at A, Figure 17, making the curve as even as possible. Then stone the faces until this curve is brought up to a sharp edge at the point between the two pen-legs forming the point.[37] Next take a piece of 000 French emery paper, lay it upon some flat body like the blade of a square, and smooth the curve of the edge enough to take off the fine, sharp edge left by the oil-stone; then apply the outside flat faces of the pen to the emery paper again, bringing the pen-edge up sharp. The emery paper will simply have smoothed and polished the surfaces, still leaving them too sharp, so sharp as to cut the paper, and to take off this sharp edge (which must first be done on the inside faces) open the pen-points as wide as the screw will permit. Then wrap one thickness of the emery paper upon a thin blade, as upon a drawing-triangle, and pass the open pen-points over it, and move the instrument endwise, taking care to keep the inside face level with the surface of the emery paper, so that the pen-points shall not cut through. Next close the pen-points with the screw until they nearly, but not quite, touch, and sweep the edge of the pen-point along the emery paper under a slight pressure, so moving the handle that at each stroke the whole length around the curved end of the pen will meet the emery surface. During this motion the inside faces of the pen-point must be held as nearly vertical as possible, so as to keep the two halves of the pen-point equal. The pen is now ready for use, and will draw a fine and clean line. It is not usual to employ emery paper for the purpose indicated, but it will be found very desirable, since it leaves a smoother surface and edge than the oil-stone alone. Circle-pens are more difficult to put in order than [38] the straight-line pen, especially those for drawing the smallest circles, which cannot be well drawn unless the pen is of the precise right shape and in the best condition. A circle-pen is shown in Figure 24, in which A represents the point-leg and B the pen-leg. The point-leg must be the longest because it requires to enter the drawing paper before the pen meets the surface. The point should be sharp and round, for any edges or angles on it will cause it to widen the hole in the paper when it is rotated. To shape the points to prevent the enlargement of the centre in the paper is one of the most important considerations in the use of this instrument, especially when several circles require to be drawn from the same centre. To accomplish this end the inside of the point-leg should be, as near as possible, parallel to the length of the instrument (which is denoted in Figure 24 by the dotted line) when the legs are closed, as in the figure. If the point is at an angle, as shown in Figure 25, it is obvious that rotating it will enlarge the top of the centre in the drawing paper. The point should be sharp and smooth on its circumferential surface, and so much longer than the pen-point that it will have sufficient hold in the paper when the instrument stands vertical and the pen-point meets the surface of it, which amount is about 1/64th of an inch. We may now consider the shape of the pen-point. Its inside surfaces should be flat across and to the curve shown in Figure 24, not as shown exaggerated in Figure 25, because in the latter the body of the ink will be too near the pen-point, and but little can be placed [39] in it without causing it sometimes to flow over the edges and down the outside of the pen. A form of pen-point recently introduced is shaped as in Figure 26, the object being to have a thin stream of ink near the marking pen-point and the main body of the ink near at hand, instead of extending up the pen, as would be the case with Figure 24. The advantage thus gained is that the ink lies in a more solid body, and having less area of surface exposed to the air will not dry so quickly in the pen; but this is more than offset by the liability of the ink to flow over the crook at A, and cause the pen to draw a thick ragged line. The pen-point must be slightly inclined toward the needle-point, to the end that they may approach each other close enough for drawing very small circles, but it should also stand as nearly vertical as will permit that end to be attained. As this pen is for drawing small circles only, it does not require much ink, and hence may be somewhat close together, as in Figure 24; this has the advantage that the point is not hidden from observation. In forming the pen-point the greatest refinement is necessary to enable the drawing of very small true circles, say 1/16th of an inch, or less, in diameter. The requirements are that the pen-point shall meet the surface of the paper when the needle-point has entered it sufficiently to give the necessary support, and that the instrument shall stand vertical, as shown by the dotted line in Figure 24. Also, that the pen shall then touch the paper at a point only, this point being the apex of a fine curve; that this curve be equal on each side of the point of contact with the paper; that [40] both halves forming the pen be of equal thickness and width at the pointed curve; and that the point be as sharp as possible without cutting the paper. The best method of attaining these ends is as follows: On each side of the pen make, with an oil-stone, a flat place, as C D, Figure 27 (where the pen-point is shown magnified), thus bringing both halves to an edge of exactly equal length, and leaving the point flat at D. These flat places must be parallel to one another and to the joint between the two halves of the pen. As the oil-stone may leave a slightly ragged edge, it is a good plan to take a piece of 00 French emery paper, lay it on a flat surface, and holding the instrument vertically remove the fine edge D until it will not cut. Then with the oil-stone shape the curved edge as in Figure 28, taking care that the curve no more than brings the flat place D up to a true curve and leaves the edge sharp, with only the very point touching the paper, which is represented in the cut by the horizontal line. The point must have a sharp edge all around the curve, and the two halves must be exactly equal in width, for if one half is wider than the other, as in Figure 29 at a, or as in Figure 30 at b, it will be impossible to draw a very small circle true. So, likewise, the two halves of the pen must be of exactly [41] equal length, and not one half longer than the other, as in Figures 31 or 32, which would tend to cut the paper, and also render the drawing of true small circles impracticable. When the pen is closed to draw a very small circle the two halves of the pen-leg should have an equal degree of contact with the surface of the paper, and then as the legs are opened out to draw larger circles the contact of the outside half of the pen will have less contact with the paper. The smaller the circle, the more difficult it is to keep the point-leg from slipping out of the centre, and the more difficult it is to draw a clear line and true circle; hence the points should be shaped to the best advantage for drawing these small circles, by oil-stoning the pen, as already described, and then finishing it as follows: After the oil-stoning, open the two valves of the pen-leg wide enough to admit a piece of 000 French emery paper wrapped once around a very thin blade, and move the pen endwise as described for the straight-line pen. This will smooth the inner surfaces and remove any fine wire-edge that the oil-stone may leave. Close the two halves of the pen again, and lightly emery-paper the outside faces, which will leave the edge sharp enough to cut the paper. The removal of the sharp edge still left, to the exact degree, requires great care. It may best be done by closing the pen until its two halves very nearly, but not quite, touch, then adjust it to mark a circle of about 3/16 inch diameter, and strike a number of circles in different locations upon the surface of a piece of 0000 French emery paper.[42] In marking these circles, however, let the instrument stand out of the perpendicular, and do very little while standing vertically. Indeed, it is well to strike a number of half-circles, first from right to left and then from left to right, and finally draw a full circle, sloping the pen on one side, gradually raising it vertically, and finally sloping it to the other side. This will insure that the pen has contact at its extreme point, and leave that point fine and keen, but not enough so to cut the paper. To test the pen, draw small circles with the pen rotated first in one direction and then in the other, closing its points so as to mark a fine line, which, if the pen is properly shaped, will be clear and fine, while if improperly formed the circle drawn with the pen rotated in one direction will not coincide with that drawn while rotating it in the other. The same circle may be drawn over several times to make a thorough test. If a drawing instrument will draw a fine line correctly, it will be found to answer for thick lines which are more easily made. In thus preparing the instruments, the operator will find that if he occasionally holds the points in the right position with regard to the light, he will be able to see plainly if the work is proceeding evenly and equally, for if one-half of the pen is thicker at the point or edge than the other, it will show a brighter line. This is especially the case with instruments that have become dull by use, for in that case the edges will be found quite bright, and any inequality of thickness shows plainly. It follows, from what has been said, that the needle-point and pen-point should stand vertical when in use, [43] and to effect this the instruments, except in the smallest sizes, are provided with joints, such as shown at A and B in the bow-pencil or circle-pencil, in Figure 33. These joints should be sufficiently stiff that they will not move too easily, and yet will move rather than that the legs should sensibly spring without moving at the joint. The needle-point leg should be adjusted by means of the joint, to stand vertical, and the same remarks apply equally to the pen-leg; but in the case of the pencil-leg it is the pencil itself and not the leg that requires attention, the joint B being so adjusted that the pencil either stands vertical, or, what is perhaps preferable, so that [44] it stands inclined slightly towards the needle-point. In sharpening the pencil the inner face C may be made concave or at least vertical and flat, and the outer convex or else bevelled and flat, producing a fine and long edge rounded in its length of edge. In using the circle-pencil and circle-pen it will be found more convenient to rotate it in the direction of the arrow in Figure 34. It should be held lightly to the paper, and the learner will find that he has a natural tendency to hold it too firmly and press it too heavily, which is especially to be avoided. If in drawing a small circle the needle-point slips out of the paper, it is because the pencil-point is too long; or, what is the same thing, the needle-point does not protrude far enough out from the leg. Or if the instrument requires to be leaned over too much to make the pencil or pen mark, it is because the pen or pencil is not far enough out, and this again may cause the needle-point to slip out of the paper. In Figure 35 is shown a German instrument especially [45] designed to avoid this slipping. The peculiarity of this instrument consists in the arrangement of the centre point, which remains stationary whilst the pen or pencil, resting by its own weight on the paper, is guided round by gently turning, without pressure, the small knob at the upper end of the tube. By this [46] means the misplacing or sliding of the centre-point and the cutting of the paper by the pen are avoided. By means of this fixed centre-point any number of concentric circles may be drawn, without making a hole of very distinguishable size on the paper. In applying the ink to the bow-pen as to all other instruments, care must be taken that the ink lies between the points only and not on the outside, for in the latter case the ink will flow down too freely and make a broad, ragged line, perhaps getting on the edge of the square blade or triangle, and causing a blot of ink on the drawing. [47] In using a straight line or lining pen with a T square it may be used as in Figure 36, being nearly vertical, as shown, and moved from left to right as denoted by the arrow, S representing the square blade. But in using it, or a pencil, with a straight edge or a triangle unsupported by the square blade, the latter should be steadied by letting the fingers rest upon it while using the instrument, the operation being shown in Figure 37. The position, Figure 36, is suitable for long lines, and that in Figure 37 for small drawings, where the pen requires close adjustment to the lines. CHAPTER III.LINES AND CURVES.Although the beginner will find that a study of geometry is not essential to the production of such elementary examples of mechanical drawing as are given in this book, yet as more difficult examples are essayed he will find such a study to be of great advantage and assistance. Meantime the following explanation of simple geometrical terms is all that is necessary to an understanding of the examples given. The shortest distance between two points is termed the radius; and, in the case of a circle, means the distance from the centre to the perimeter measured in a straight line. Dotted lines, thus, <——- >, mean the direction and the points at which a dimension is taken or marked. Dotted lines, thus,——-, simply connect the same parts or lines in different views of the object. Thus in [49] Figure 38 are a side and an end view of a rivet, and the dotted lines show that the circles on the end view correspond to the circle of the diameters of the head and of the stem, and therefore represent their diameters while showing that both are round. A straight line is in geometry termed a right line. A line at a right angle to another is said to be perpendicular to it; thus, in Figures 39, 40, and 41, lines A are in each case perpendicular to line B, or line B is in each case perpendicular to line A. A point is a position or location supposed to have no size, and in cases where necessary is indicated by a dot. Parallel lines are those equidistant one from the other throughout their length, as in Figure 42. Lines maybe parallel though not straight; thus, in Figure 43, the lines are parallel. A line is said to be produced when it is extended beyond its natural limits: thus, in Figure 44, lines A and B are produced in the point C. A line is bisected when the centre of its length is marked: thus, line A in Figure 45 is bisected, at or in, as it is termed, e. The line bounding a circle is termed its circumference or periphery and sometimes the perimeter. A part of this circumference is termed an arc of a circle or an arc; thus Figure 46 represents an arc. When this arc has breadth it is termed a segment; thus Figures 47 and 48 are segments of a circle. A straight line cutting off an arc is termed the chord of the arc; thus, in Figure 48, line A is the chord of the arc. A quadrant of a circle is one quarter of the same, [51] being bounded on two of its sides by two radial lines, as in Figure 49. When the area of a circle that is enclosed within two radial lines is either less or more than one quarter of the whole area of the circle the figure is termed a sector; thus, in Figure 50, A and B are both sectors of a circle. A straight line touching the perimeter of a circle is said to be tangent to that circle, and the point at which it touches is that to which it is tangent; thus, in Figure 51, line A is tangent to the circle at point B. The half of a circle is termed a semicircle; thus, in Figure 52, A B and C are each a semicircle. The point from which a circle or arc of a circle is drawn is termed its centre. The line representing the centre of a cylinder is termed its axis; thus, in Figure 53, dot d represents the centre of the circle, and line b b the axial line of the cylinder. To draw a circle that shall pass through any three given points: Let A B and C in Figure 54 be the points through which the circumference of a circle is to pass. Draw line D connecting A to C, and line E connecting B to C. Bisect D in F and E in G. From F as a centre draw the semicircle O, and from G as a centre draw the semicircle P; these two semicircles meeting the two ends of the respective lines D E. [52] From B as a centre draw arc H, and from C the arc I, bisecting P in J. From A as a centre draw arc K, and from C the arc L, bisecting the semicircle O in M. Draw a line passing through M and F, and a line passing through J and Q, and where these two lines intersect, as at Q, is the centre of a circle R that will pass through all three of the points A B and C. To find the centre from which an arc of a circle has been struck: Let A A in Figure 55 be the arc whose centre is to be found. From the extreme ends of the arc bisect it in B. From end A draw the arc C, and from B the arc D. Then from the end A draw arc G, and from B the arc F. Draw line H passing through the two points of intersections of arcs C D, and line I passing through the two points of intersection of F G, and where H and I meet, as at J, is the centre from which the arc was drawn. A degree of a circle is the 1/360 part of its circumference. The whole circumference is supposed to be divided into 360 equal divisions, which are called the [53] degrees of a circle; but, as one-half of the circle is simply a repetition of the other half, it is not necessary for mechanical purposes to deal with more than one-half, as is done in Figure 56. As the whole circle contains 360 degrees, half of it will contain one-half of that number, or 180; a quarter will contain 90, and an eighth will contain 45 degrees. In the protractors (as the instruments having the degrees of a circle marked on them are termed) made for sale the edges of the half-circle are marked off into degrees and half-degrees; but it is sufficient for the purpose of this explanation to divide off one quarter by lines 10 degrees apart, and the other by lines 5 degrees apart. The diameter of the circle obviously makes no difference in the number of decrees contained in any portion of it. Thus, in the quarter from 0 to 90, there are 90 degrees, as marked; but suppose the diameter of the circle were that of inner circle d, and one-quarter of it would still contain 90 degrees. So, likewise, the degrees of one line to another are not always taken from one point, as from the point O, but from any one line to another. Thus the line marked 120 is 60 degrees from line 180, or line 90 is 60 degrees from line 150. Similarly in the other quarter of the circle 60 degrees are marked. This may be explained further by stating that the point O or zero may be situated at the point from which the degrees of angle are to be taken. Here it may be remarked that, to save writing the word "degrees," it is usual to place on the right and above the figures a small °, as is done in Figure 56, the 60° meaning sixty degrees, the °, of course, standing for degrees. Suppose, then, we are given two lines, as a and b in Figure 57, and are required to find their angle one to the other. Then, if we have a protractor, we may apply it to the lines and see how many degrees of angle they contain. This word "contain" means how many degrees of angle there are between the lines, [55] which, in the absence of a protractor, we may find by prolonging the lines until they meet in a point as at c. From this point as a centre we draw a circle D, passing through both lines a, b. All we now have to do is to find what part, or how much of the circumference, of the circle is enclosed within the two lines. In the example we find it is the one-twelfth part; hence the lines are 30 degrees apart, for, as the whole circle contains 360, then one-twelfth must contain 30, because 360÷12 = 30. If we have three lines, as lines A B and C in Figure 58, we may find their angles one to the other by projecting or prolonging the lines until they meet as at points D, E, and F, and use these points as the centres wherefrom to mark circles as G, H, and I. Then, from circle H, we may, by dividing it, obtain the angle [56] of A to B or of B to A. By dividing circle I we may obtain the angle of A to C or of C to A, and by dividing circle G we may obtain the angle of B to C or of C to B. It may happen, and, indeed, generally will do so, that the first attempt will not succeed, because the distance between the lines measured, or the arc of the circle, will not divide the circle without having the last division either too long or too short, in which case the circle may be divided as follows: The compasses set to its radius, or half its diameter, will divide the circle into 6 equal divisions, and each of these divisions will contain 60 degrees of angle, because 360 (the number of degrees in the whole circle) ÷6 (the number of divisions) = 60, the number of degrees in each division. We may, therefore, subdivide as many of the divisions as are necessary for the two lines whose degrees of angle are to be found. Thus, in Figure 59, are two lines, C, D, and it is required to find their angle one to the other. The circle is divided into six divisions, marked respectively from 1 to 6, the division being made from [57] the intersection of line C with the circle. As both lines fall within less than a division, we subdivide that division as by arcs a, b, which divide it into three equal divisions, of which the lines occupy one division. Hence, it is clear that they are at an angle of 20 degrees, because twenty is one-third of sixty. When the number of degrees of angle between two lines is less than 90, the lines are said to form an acute angle one to the other, but when they are at more than 90 degrees of angle they are said to form an obtuse angle. Thus, in Figure 60, A and C are at an acute angle, while B and C are at an obtuse angle. F and G form an acute angle one to the other, as also do G and B, while H and A are at an obtuse angle. Between I and J there are 90 degrees of angle; hence they form neither an acute nor an obtuse angle, but what is termed a right-angle, or an angle of 90 degrees. E and B are at an obtuse angle. Thus it will be perceived that it is the amount of inclination of one line to another that determines its [58] angle, irrespective of the positions of the lines, with respect to the circle. TRIANGLES. A right-angled triangle is one in which two of the sides are at a right angle one to the other. Figure 61 represents a right-angled triangle, A and B forming a right angle. The side opposite, as C, is called the hypothenuse. The other sides, A and B, are called respectively the base and the perpendicular. An acute-angled triangle has all its angles acute, as in Figure 63. An obtuse-angled triangle has one obtuse angle, as A, Figure 62.[59] When all the sides of a triangle are equal in length and the angles are all equal, as in Figure 63, it is termed an equilateral triangle, and either of its sides may be called the base. When two only of the sides and two only of the angles are equal, as in Figure 64, it is termed an isosceles triangle, and the side that is unequal, as A in the figure, is termed the base. When all the sides and angles are unequal, as in Figure 65, it is termed a scalene triangle, and either of its sides may be called the base. The angle opposite the base of a triangle is called the vertex. A figure that is bounded by four straight lines is termed a quadrangle, quadrilateral or tetragon. When opposite sides of the figure are parallel to each [60] other it is termed a parallelogram, no matter what the angle of the adjoining lines in the figure may be. When all the angles are right angles, as in Figure 66, the figure is called a rectangle. If the sides of a rectangle are of equal length, as in Figure 67, the figure is called a square. If two of the parallel sides of a rectangle are longer than the other two sides, as in Figure 66, it is called an oblong. If the length of the sides of a parallelogram are all equal and the angles are not right angles, as in Figure 68, it is called a rhomb, rhombus or diamond. If two of the parallel sides of a parallelogram are longer than the other two, and the angles are not right angles, as in Figure 69, it is called a rhomboid. If two of the parallel sides of a quadrilateral are of unequal lengths and the angles of the other two sides are not equal, as in Figure 70, it is termed a trapezoid. If none of the sides of a quadrangle are parallel, as in Figure 71, it is termed a trapezium. [61] THE CONSTRUCTION OF POLYGONS. The term polygon is applied to figures having flat sides equidistant from a common centre. From this centre a circle may be struck that will touch all the corners of the sides of the polygon, or the point of each side that is central in the length of the side. In drawing a polygon, one of these circles is used upon which to divide the figure into the requisite number of divisions for the sides. When the dimension of the polygon across its corners is given, the circle drawn to that dimension circumscribes the polygon, because the circle is without or outside of the polygon and touches it at its corners only. When the dimension across the flats of the polygon is given, or when the dimension given is that of a circle that can be inscribed or marked within the polygon, touching its sides but not passing through them, then the polygon circumscribes or envelops the circle, and the circle is inscribed or marked within the polygon. Thus, in Figure 71 a, the circle is inscribed within the polygon, while in Figure 72 the polygon is circumscribed by the circle; the first is therefore a circumscribed and [62] the second an inscribed polygon. A regular polygon is one the sides of which are all of an equal length. NAMES OF REGULAR POLYGONS.

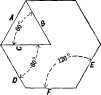

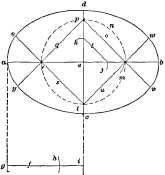

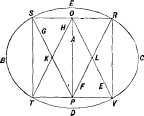

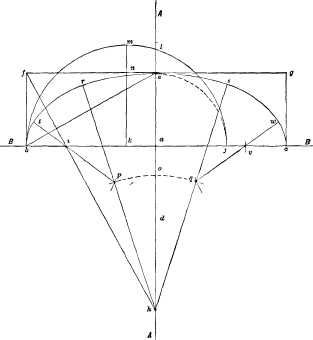

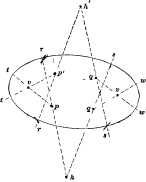

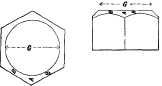

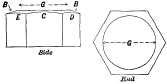

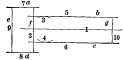

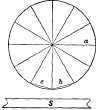

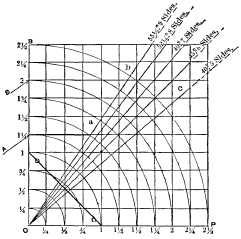

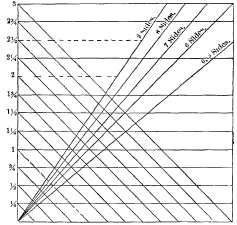

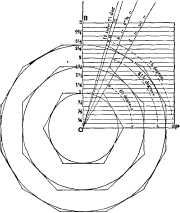

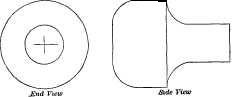

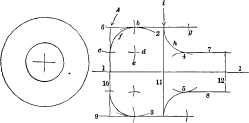

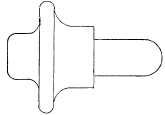

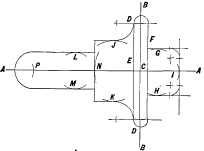

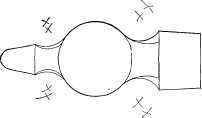

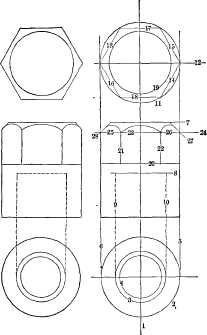

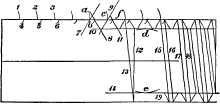

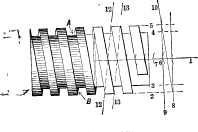

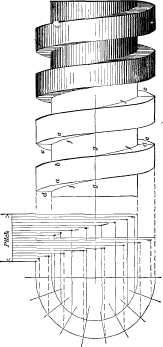

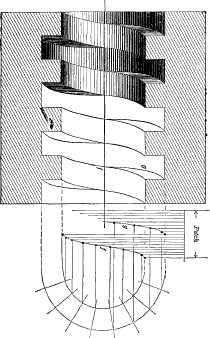

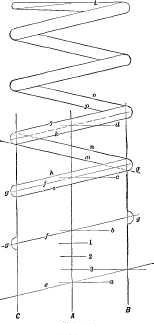

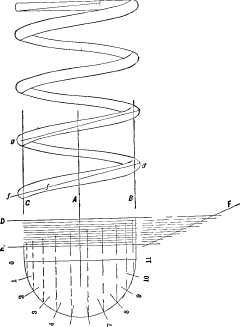

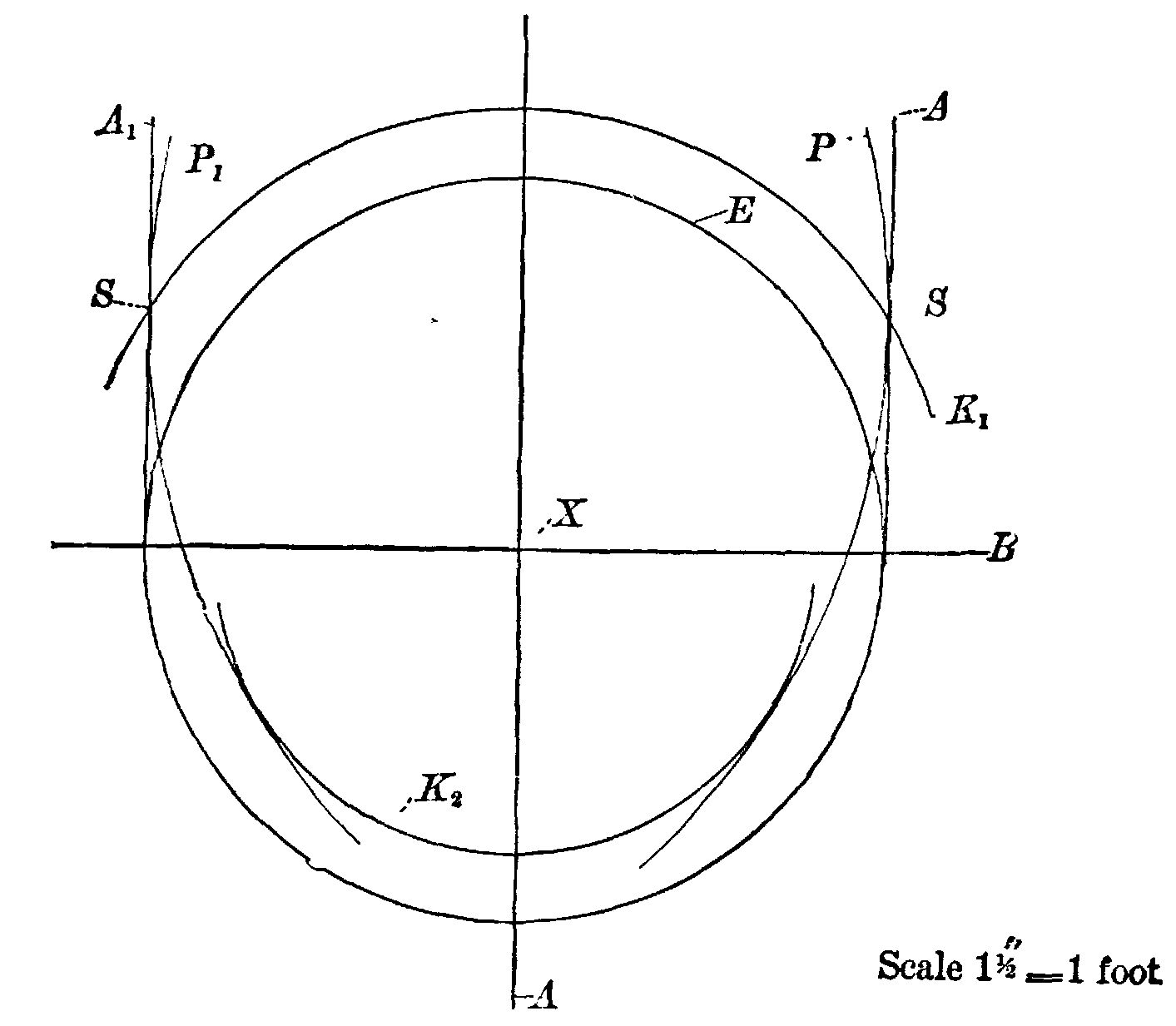

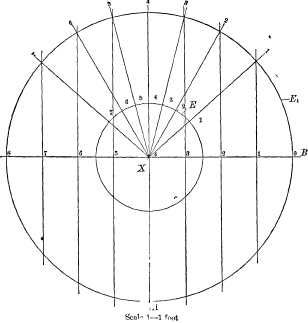

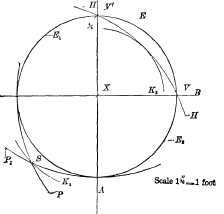

The angles of regular polygons are designated by their degrees of angle, "at the centre" and "at the circumference." By the angle at the centre is meant the angle of a side to a radial line; thus in Figure 73 is a hexagon, and at C is a radial line; thus the angle of the side D to C is 60 degrees. Or if at the two ends of a side, as A, two radial lines be drawn, as B, C, then the angles of these two lines, one to the other, will be the "angle at the centre." The angle at the circumference is the angle of one side to its next neighbor; thus the angle at the circumference in a hexagon is 120 degrees, as shown in the figure for [63] the sides E, F. It is obvious that as all the sides are of equal length, they are all at the same angle both to the centre and to one another. In Figure 74 is a trigon, the angles at its centre being 120, and the angle at the circumference being 60, as marked. The angles of regular polygons: